Bendicrop 60 Hydraulic Ironworker

The Geka Bendicrop 60 ironworker machine is part of Geka’s Bendicrop Series of ironworkers with integrated bending stations, an unique feature on the market. In total, these machines have six workstations for different metalworking tasks.

Hydraulic ironworker with an integrated bending station

The Bendicrop 60 ironworker, for sale from Geka distributors and dealers, features two cylinders, allowing it to be used by two operators simultaneously. The machine has a punching power of 67 US tons and comes in two versions: an S version with a standard throat length of 10″ and an SD version with an extended throat length of 20″.

BENDICROP 60 FEATURES AND SPECIFICATIONS

| FEATURES | BENDICROP 60 |

|---|---|

| Punching Power | 67 US Tons |

| Punching | Ø 1 1/2″ x 7 16″ |

| Shearing flat bars | 14″ x 3/8″ (5º) 14″ x 1/2″ |

| Shear of angle section L at 90 | 5″ x 5″ x 3/8″ |

| Bending | 6″ x 3/8″ |

| Notching (triangular) | 4″ x 3/8″ |

- Capacities based on a material resistance of 65,000 tensile.

- The manufacturer reserves the right to make modifications without prior notice.

The machine features a blade holder with vertical movement, improving the accuracy of all of its workstations. The six workstations in the Bendicrop ironworkers handle the following tasks:

- Punching

- Notching

- Shearing flat bars

- Cutting angles

- Shearing round and square bars

- Bending (built-in station)

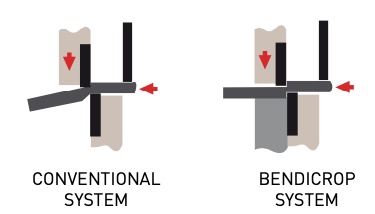

The Bendicrop machines also feature Geka’s anti-torsion system that reduces the deformation of material when shearing flat bars.

It is also fitted with a touch and cut length stop and is delivered with two V-shaped bending dies of 1.5” and 2.7”.

Two different versions of the Bendicrop 60 Ironworker are available, differing in their throat lengths:

S Version: 10” Standard Throat.

SD Version: 20” Extended Throat.

Main Features in the Geka Bendicrop Series

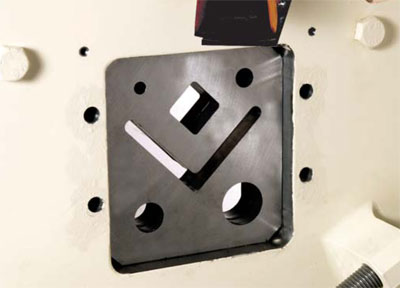

The punching station features a goose neck die-holder for punching profile sections on legs and webs. Punches and dies may be changed very easily and the die holder is also adjustable to align tools. The punching table includes scales.

Precise shearing of angles and round and square bars without loss of material.

The shearing system for flat bars and plates offers minimum deformation of material and a very sturdy table marked out with degrees, allowing operators to set up non-square cuts easily. Two material guides are also included.

The machine may perform triangular notching operations and features a gauge table with scales to facilitate this task. The notching station may also perform pipe and tube notching, rectangular notching, punching (as a secondary punching station) or the notching of special shapes.

Bendicrop main features:

|  |  |  |  | |

| Max Punching Ø | Flat Bars Shearing | Angle cut 90º | Notching | Bending | |

| Bendicrop 50 | 1 1/4 x 1/2” 1 1/16 x 1/2” | 14” x 9/16” (5º) 14” x 1/2” | 3” x 3” x 5/16” | Rectangular 4″ x 3/8” | 4” x 3/8” |

| Bendicrop 60 | 1 1/2” x 7⁄16” | 14” x 9/16” (5º) 14” x 1/2” | 4” x 4” x 1/2” | Triangular 4″ x 3/8” | 6” x 3/8” |

| Bendicrop 85 | 1 1/2” x 1/2” | 18” x 5/8” (5º) 18” x 3/4” | 4” x 4” x 1/2” | Triangular 5″ x 1/2” | 8” x 1/2” |

- Capacities based on a material resistance of 65,000 tensile.

- The manufacturer reserves the right to make modifications without prior notice.

CNC Feeders and Positioners for GEKA Ironworkers and Punching Machines

Increase the productivity and time-efficiency of your Geka ironworker with our CNC positioners and feeders, which automate the task of positioning plates and profiles in the punching and shearing stations.

Services for your Bendicrop Ironworker

Choose below the service you want to contact with.

Sales Consultant

Ask our experienced sales consultants to provide you extensive information and advice.

Brochure Request

You can ask for any brochure or information about any of our products.

Technical Support

Ask for technical support or service to our GEKA qualified engineers.

Manuals Request

You can request our free manuals for your machine or GEKA or original tool.