With the aim of eliminating permanent deformations that may occur in the material when shearing, the Bendicrop Series of hydraulic ironworkers are equipped with a patented anti-twist system, which is a non-deformation shearing system for cutting plates with the minimum deformation possible. This anti-twist system is specially designed so that the user can work cutting materials that are softer than steel, such as copper or aluminum, obtaining exceptional cutting results.

How does the anti-twist system work?

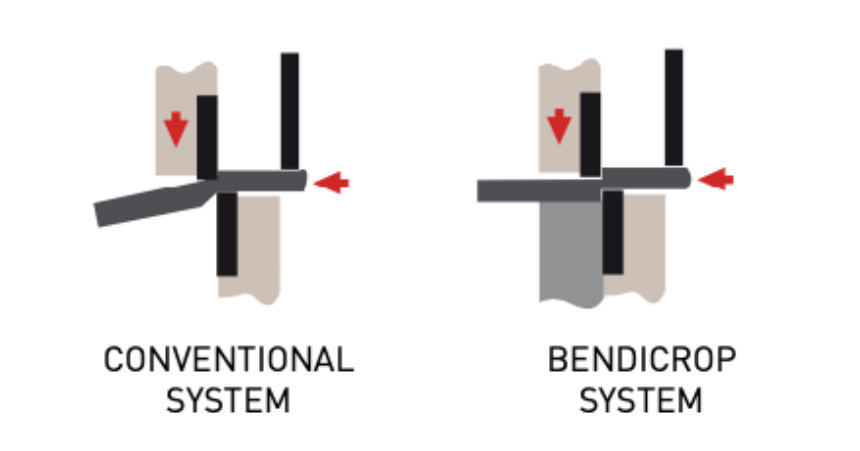

The patented anti-twist metalworker in our Bendicrop Series ironworkers is different from other conventional systems. While the conventional systems that are used with the purpose of cutting steel are slightly bent and do not have a holder underneath, Bendicrop’s anti-twist system is completely straight vertically and has a holder below it that keeps it straight. This way, when trying to cut flat bars made of materials that are not as firm as steel, they will not twist, and deformation will be exponentially reduced. This is how you will obtain exceptional cutting results when cutting or shearing any type of materials with Bendicrop’s hydraulic ironworkers.The following image illustrates the difference between a conventional twist system and the one included in our Bendicrop machines.Bendicrop hydraulic Ironworker series specifications

These are the main specifications of the three hydraulic ironworkers in the Bendicrop Series of hydraulic ironworkers. All of them include our unique anti-twist system.| Features | Bendicrop 50 | Bendicrop 60 | Bendicrop 85 |

| Punching Power | 55 US Tons | 67 US Tons | 93 US Tons |

| Punching | Ø 1-1/16” x 1/2′′ | Ø 1 1/2′′ x 7 16′′ | Ø1-9/16” x 1⁄2” |

| Shearing flat bars | 14 x 3/8′′@ 2o 14 x 1/2′′@4o | 14′′ x 3/8′′ (5o) 14′′ x 1/2′′ | 18” x 5/8” @ 2.5o 18” x 7/8” @ 5o |

| Shear of angle section L at 90 | 3” x 3” x 5/16 | 5′′ x 5′′ x 3/8′′ | 4” x 4” x 1/2” |

| Bending | 4” x 3/8” with 2 “V” dies of 1-5/8” and 2-3/4” Openings | 6′′ x 3/8′′ | 8” x 1⁄2” with 2 “V” dies of 2” and 3-1/2” Openings |

| Notching | Rectangular 3/8” Width of Notcher 1- 9/16” Depth of Cut 3/8” | Triangular 4′′ x 3/8′′ | Triangular 5” x 5” x 1⁄2” |

| Round and Square Bar Shearing | Ø1-3/8” Round Ø1-3/16” Square | N/A | Ø1-3/4” Round 1-9/16” Square |

- Capacities based on a material resistance of 65,000 tensile strength.

- The manufacturer reserves the right to make modifications without prior notice.